Applications

Unlock new capabilities. Explore new opportunities. Empower your workers to work better, faster, and more efficiently. With a customized software solution, you�ll maximize your throughput all while reducing your costs.

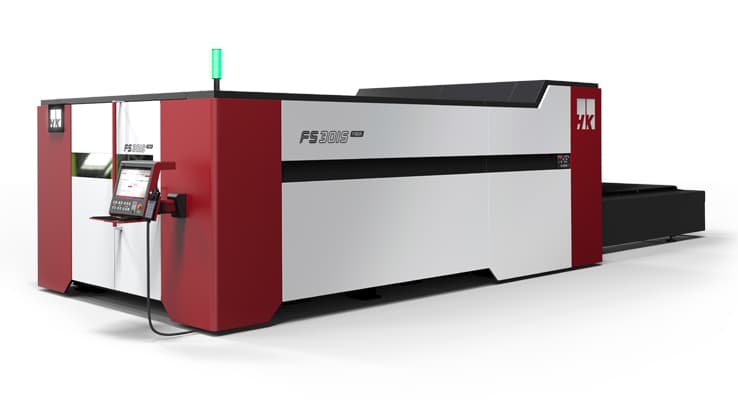

It means that when working with metals that reflect laser beams they absorb fiber laser light much faster than the CO2 laser light.